Samtech pcba cutter can apply to LED panel,pcb board,fiberboard,aluminum plate,aluminum substrate, copper substrate,

FR4, glass fiber board and so on.

Our wedsite: www.pcb-separator.com

More SMT periphery machine Youtube video channel link: https://www.youtube.com/channel/UCJhVJS_v0n6LQKNEBsekUyg

PCB separator CAB Maestro 4M 基板分割機 V溝基板分割機 feeding PCB cutting machine depanelizing pcb v-cut scoring mach from PCB separator

www.pcb-separator.com

http://ascen.en.gongchang.com/

PCB separator CAB Maestro 4M 基板分割機 V溝基板分割機 feeding PCB cutting machine depanelizing pcb v-cut scoring machine Vカット分割機,基板分割機・基盤切断機 PCB Cutting tool

Email:Jasonzhang@pcbasc.com

Skype: supplier889

Phone: 8615989222889

ASC-505 feeding PCB cutter features:

1.The circular blade moves horizontally and the straight knife moves up and down to cut

the board with the pcb staying, thus the electronic elements won’t be damaged.

2.With microcomputer technology, the program can control the cutting schedule and cutting

times with storage of up to 100 groups of data. This machine is suitable for width from

58mm to 220mm of board.

3.The gap between the upper and lower blade is adjustable, the adjustable range is from

0mm to 15mm.

4.The straight blade moves up and down, which is available to cut double-sided board.

5.The cutting press is smaller to avoid solder crack.

6.The manual switch controls the cutting speed of 1 cut/s.

7.No need to feeding boards manually with high-tech device, there are reserved port for

external robotic hand.

8.Using air press from 4 to 5 Pa, no demand for specific working place, wipe its surface

with rust-proof oil for the maintenance.

9.The productivity is visible due to the auto counter performance.

10.With safety device of Omron infrared light sensor, the machine stops operation when

it senses the hand or foreign matter in the moving zone of the blade.

11. With step motor, the machine locks by itself and positioning accurately when in

an energized state.

12.When the solder panel with many pieces of boards is separated, it’s easy to hurt the

elements or the circuit. While this machine is available to avoid the damages and

improve working efficiency and quality.

13.After cutting the pcb, the boards can be transferred directly to the inspection line

through the conveyor belt.

ASC-505 pcb cutting machineTechnical specifications:

|

Machine dimension: |

1100×630×730mm |

|

Maximum cutting length: |

300mm |

|

Cutting width: |

58mm-220mm |

|

Cutting thickness: |

0.2-3mm |

|

Voltage: |

AC 230V/110V |

|

Cutting speed: |

1 V-cut/s |

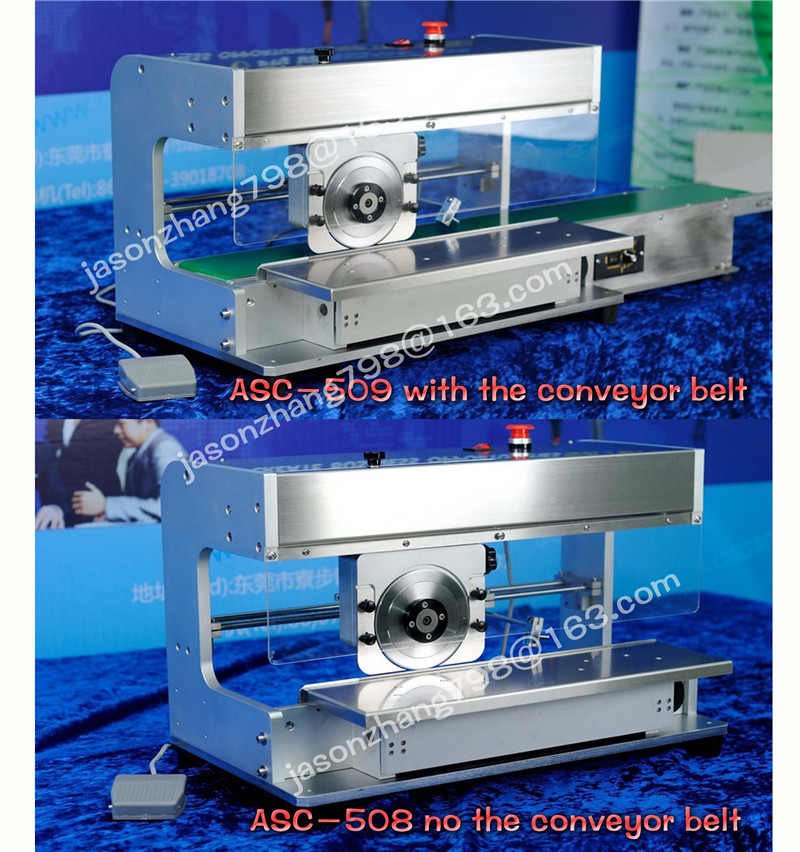

ASC-508/509 pcb cutting machineTechnical specifications:

conveyor belt size: 1040mm(L) x 142mm(W) x 127mm(H) weight:11.3KG

conveyor belt packing size: 1090mm(L) x 192mm(W) x 177mm(H) weight:12.3KG

|

Model number |

ASC-508 (no conveyor belt) |

ASC-509 (with conveyor belt) |

|

Machine size |

600*395*425mm |

600*395*425mm |

|

Packing size |

640*420*450mm |

640*420*450mm |

|

Size of the conveyor belt |

none |

1040mm*142mm*127mm |

|

Knife material |

SHD61 imported high-speed steel |

SHD61 imported high-speed steel |

|

Cutting speed |

300,500mm/s |

300,500mm/s |

|

Cutting thickness |

0.2-5mm |

0.2-5mm |

|

circular knife size |

125mm(diameter) |

125mm(diameter) |

|

Blade length |

360mm(length) |

360mm(length) |

|

Voltage |

AC220/110V 50-60HZ |

AC220/110V 50-60HZ |

|

Machine weight |

37kg |

37kg+ 11.3kg |

|

Packing weight |

49kg |

49+12.3KG |

|

Power |

40W |

40W |

PCB cutting machine/pcb depaneling tool/PCB Depanelers/v-grooving cutting machine/V-cut separator

The machine can be in supporting use of a complete set of conveyor belt, which is convenient for the cut PCB to be send out automatically .

http://www.pcb-separator.com

http://www.smtuse.com/

The platform is adjustable. It is good for the product quality when lifting the platform, because it will reduce stress and will not hurt the product.

The spacing device applies to products of different size, so as to improve the work efficiency.

ASC-508, 509 feeding PCB cutter features:

1.ASC-508 separates both small and large pre-scored PCBs.

2.The table and the rest can be continuously adjusted to the most suitable working position. The slit between the linear blade and the rest can be adjusted to ensure that the side strips fall through and are sorted out.

3.Separation of aluminum-boards on request. Blades: Titan coated serially. Frequently for critical components an upper limit of tensile stress will be determined. Please ask us regarding possibilities to reduce tensile stress of components.

4.The PCB is placed with its pre-scored groove onto the linear blade and the circular blade is then drawn by hand across the PCB. The clearance between the upper guide and the linear blade ist adustable to ensure that the PCB is only separated in the pre-scored groove.