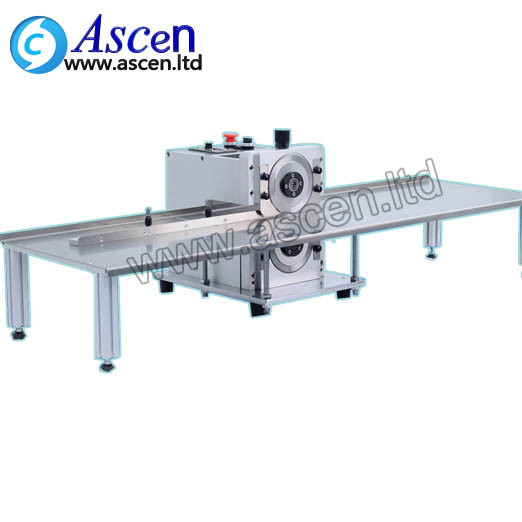

1, The Automatic PCB depaneling machine adopts the latest blade-type light weight design, which completes the micro-shear stress cutting stroke at one time, and is suitable for separating PCB circuit boards with V-grooves.

2, The product is placed on the adapted platform and moves along the guide blade. The lower round blade actively rotates and the upper round knife is rotates passively. Shear stress is reduced to the minimum, suitable for long strip aluminum substrate, LED light strip separating.

3, The tool is made of high-speed steel by precision grinding and can be repeatedly ground and used.

Product features

1, The body is made of aluminum alloy, which does not occupy space, and is easy to operate and fast speed.

2, The distance between the upper and lower knives can be accurately adjusted to solve the problem of V-CUT depth, minimize the internal stress generated during cutting and avoid tin cracking.

3, The upper and lower round knives can be precisely adjusted, and the machine can cut the PCB board and aluminum substrate with V-CUT

4, The tool is made of imported German steel, made by Taiwan professional knife company, wear-resistant, long life, and the blade can be repeatedly ground and used.

5, Surface white spray powder baking varnish is a special process, not easy to fall off

Application: long strip aluminum substrate, LED light strip,PCB circuit boards with V-grooves.

Technical parameters

| Model | ASC-501 |

| Machine dimension | 380*290*380mm |

| Maximum board length | Unlimited |

| Separating speed | 80/120/200/400mm/s |

| Board thickness | 0.2-5mm |

| Power Supply | 230V/50Hz(110V/60Hz) |

| Weight | 29kg |

| Packing size | 400*300*400*mm |

| Power | 40W |