3)Automatic screw feeding device subvert the working principle of traditional screw feeding

device by abandoning the vibration plate and pusher. It carries forward the advantages

and overcomes the disadvantages of traditional screw feeding device, making it portable,

safe, stable and fast with low noise and low energy consumption.

4) Auto screw locking machine is easy to operate:the traditional manual take aim screws and screw

holes need to take up a lot of time and energy, and equipments are constantly placed just artifacts;

5)Automatic screw fasten lockong robot with the intelligent: PLC intelligent control circuits,

configure the touchscreen, the production data at a glance;

6)The screw tightening machine with high standards: lock pay process by equipment according

to the program itself completely, avoid the ill effects of artificial wrong operation; Lock pay cycle is short,

the equipment can be embedded line body achieve streamline operations.

7)With stable performance: equipment imported raw materials, equipment, production of high

efficiency, low failure rate, good guarantee product quality, to ensure that equipment zero fault.

1. Scope of applicative screws: M2- M6

2. Scope of applicative screw heads: for any universal type such as straight slot, cross, triangle groove,

trox, hexagonal, H head, etc.

3. Surface Treatment of screw: electrolytic nickel plating, color zinc plating, white zinc plating, and copper

plating, etc.

4. Screw materials: iron, copper, stainless steel, etc.

5. Materials of products to be screwed: plastic, iron, aluminum, etc.

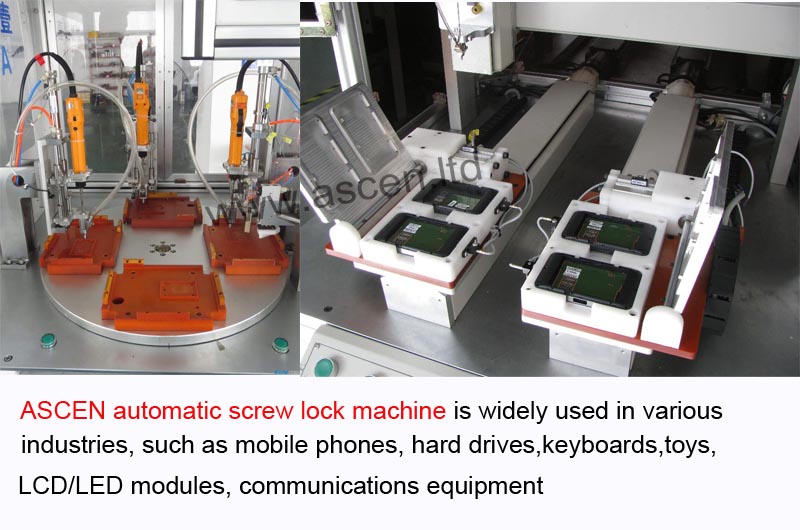

6. Applicative Industries: mobile photo, hard disk, keyboard, toy, LCD/LED modules, communication

equipment, electrical appliances, auto parts and so on.

1. Open the power, through air, adjust good torque and pressure;

2. The screw into the screw in the bin, screw amount to not more than screw conveyor altitude advisable;

3. Check if dial the code switch corresponding product model;

4. Before the first lock screw, need to check all the electricity of whether there is a grain of screw to lock

inside the clamp mouth;

5. If there is no grain of screw to lock on electric group of clamp mouth and need to press the test button,

the machine movement twice, ensure that electric batch of clip mouth there is a grain of screw batch of

clamp mouth waiting to lock in electricity;

6. Check whether feeder vibrator switch at the specified position;

7. Check finished, press the reset switch, to start production.

| Power supply | 110/220v ,50-60 Hz | |

| Drive motor | stepper motor or simple servo + belt transmission | |

| Qty of Motor control axis | 5 axis | |

| X*Y*Z working area | 480*300*80mm | |

|

Speed |

X axis | 0.1-800 mm/sec |

| Y axis | 0.1-800 mm/sec | |

| Z axis | 0.1-400 mm/sec | |

|

Repeatablity accuracy |

X axis | ±0.02mm |

| Y axis | ±0.02mm | |

| Z axis | ±0.02mm | |

|

Resolution |

X axis | 0.01mm |

| Y axis | 0.01mm | |

| Z axis | 0.01mm | |

| File storage | memory storage | |

| File storage capacity | can store 999 files , each files is more than 1000 points | |

| Speed Control | with the forward-looking spedd automatic processing | |

| Programming | High-held teaching programmer box | |

| Max Load | 12Kg | |

| Measurement | 880*690*640mm | |

The better price please sent the email to :

jasonzhang@pcbasc.com