ASCEN

Video Channel

Follow us on

ASCEN

Video Channel

Follow us on

Skype:supplier889 Email:info@ascen.ltd WhatsApp/Line/Phone:8613377777085

- PCB separator

- hektor separator/PCB hektor/off-out V-cut separator

- PCB Loaders

- PCB Unloaders

- PCB depaneling

- PCB Conveyors

- PCB Outfeed Conveyor|PCB belt conveyor

- Infeed Conveyor

- AGV car/Guided transfer robot/load efficient/magnetic navigat

- PCB magazine loader

- PCB Buffers

- Component insertion feeder

- Auto Screw Fastening Robot

- Traffic Control Conveyors

- PCB depaneling machine

- Wave Soldering

- Lead Free Reflow Oven

- PCB grooving machine

- solder dross separator

Product Description

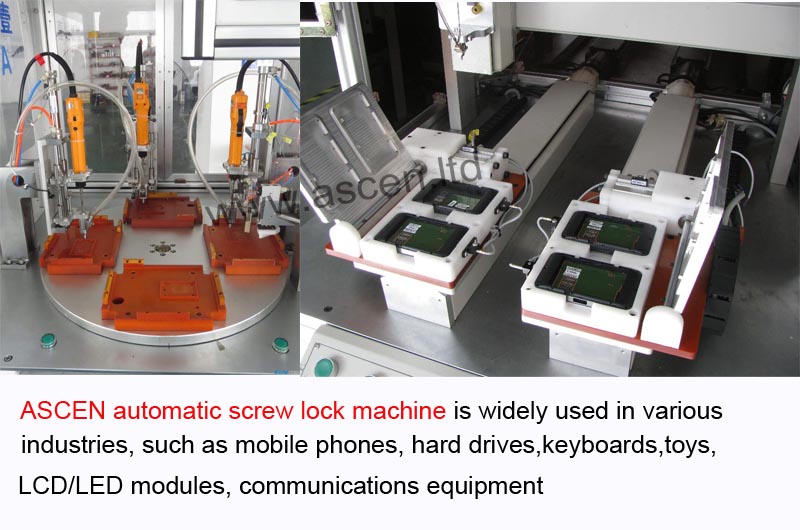

multi axis screw nut tightening robot: AS-C4 model

Intelligent multi axis screw nut tightening robot description:

1)Automatic nut locking screw machine comprises a screw automatic line unit, automatic screw conveyingunit and screw automatic tighteningunit and a detection unit locking process.

2)Intellgent double table screw automatic locking unit is mainly to the bulk of the screws are arranged neatly

and single output. The entire column unit by vibrating disksorting mechanism to achieve can also be

achieved through a rocker arm type screw arraying mechanism.

3)Automatic screw conveying unit mainly conveys the entire column screw to screw up the good single

unit job head.

4)ASCEN screw automatic nut tightening unit includes a rotary power part and screw into the part.

common screw lead-in methods are blowing type andadsorption type. In general, blowing type

because of continuous work, no need to head back and forth movement, therefore, the overallefficiency

is better than that of adsorption type. But blowing itself received screw shape and length to diameter

ratio limit, not every kind ofscrews are suitable for blowing. The detection unit comprises a drain on

floating lock lock, screw, detection card material problems.

5) Commonly used automatic locking screw machine should also include the workpiece contraposition,

screw holes on the positive function.The most common is single shaft screw system and multi axis

screw system.

6)multi axis screw locking system combined with X-Y manipulator or shifting platform can realize fully

automatic screw. XY-table type automatic locking screw machine is particularly applicable and screw bit

single workpiece porous lock, has the very high work efficiency and save more cost in the production line.

7) The double table and multi axis automatic screw lock machine is widely used in various industries,

such as mobile phones,hard drives ,keyboards,toys,LCD/LED modules, communications equipment,

electrical appliances,auto parts and other electronic processing assembly. this is the automatic production

solution for the smart factory.

Product features:

2.Flexible, universal fixtures suitable for a variety of standard models of the screw lock pay.

3.Versatility, replace the screw conveyor modules can be adapted to M1.0 ~ M4 screw lock pay.

4.Easy to put into the production line, the first to take place after the standard functions.

5.Unmanned operation,reduce labor intensity, the traditional manual placement and alignment of the screw

head of the screw would take a lot of work time and effort.

Refer standard machine video as following:

The more operation video: https://www.youtube.com/channel/UCJhVJS_v0n6LQKNEBsekUyg

Specifications:

|

The better price please sent the email to :

jasonzhang@pcbasc.com

Whether you'd like to get more info on what,why and how we do what we do, need help with what you're creating,would line to partner up or just say hi!

—--- We'd love to hear from you.

Note : Your information detail will not be published. Required fields are marked*

ASCEN

ASCEN ASCEN

ASCEN ASCEN

ASCEN