ASCEN

Video Channel

Follow us on

ASCEN

Video Channel

Follow us on

Skype:supplier889 Email:info@ascen.ltd WhatsApp/Line/Phone:8613377777085

PRODUCTS

- PCB separator

- hektor separator/PCB hektor/off-out V-cut separator

- PCB Loaders

- PCB Unloaders

- PCB depaneling

- PCB Conveyors

- PCB Outfeed Conveyor|PCB belt conveyor

- Infeed Conveyor

- AGV car/Guided transfer robot/load efficient/magnetic navigat

- PCB magazine loader

- PCB Buffers

- Component insertion feeder

- Auto Screw Fastening Robot

- Traffic Control Conveyors

- PCB depaneling machine

- Wave Soldering

- Lead Free Reflow Oven

- PCB grooving machine

- solder dross separator

SOLUTIONS

CONTACT US

SOLUTIONS

Product Description

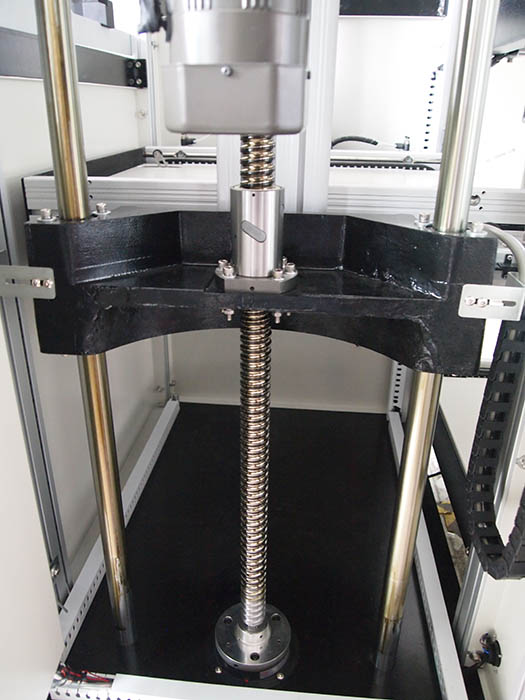

Automatic PCB magazine Unloader

Application:

The Automatic Unloader is designed for unloading of PCBs, an arriving PCB is taken up by the attached conveyor and then pushed into the magazine by a specially designed pusher. The magazine indexes to the next position and is ready for the following unloading cycle. Connect with SMT and AI production line, safety design ensure not to break any PCB when it is pushed and thus reduce defect rate. Agility operation with high accuracy, automatic counting, fault alarm functions, it is required for a full range of automatic equipment.

Japan Keyence sensor control

LCD touch screen control

Cast aluminum integrated lifting platform

light tower and audible alarm

CE compliance.

2 year parts warranty

Technical Specifications:

Selectable pitch 10mm up to 40mm

Auto/Manual run modes

Diameter 3mm edge round belt

Component clearance: top 80mm bottom 20mm

Power: AC220V/110V, 50/60 HZ, 1 phase

Air Pressure: 5kgf/cm2

PCB Convey Direction: L-R ( Or R-L)

Front rail fixed ( or rear rail fixed)

Conveyor height:900+-20mm( standard height for SMT application)

For AI application, please specify the height requirements

Magazine max pcb width available at 250mm(S), 330mm(M), 390mm(L), 460mm(X)

Order and Shipping Info:

Application:

The Automatic Unloader is designed for unloading of PCBs, an arriving PCB is taken up by the attached conveyor and then pushed into the magazine by a specially designed pusher. The magazine indexes to the next position and is ready for the following unloading cycle. Connect with SMT and AI production line, safety design ensure not to break any PCB when it is pushed and thus reduce defect rate. Agility operation with high accuracy, automatic counting, fault alarm functions, it is required for a full range of automatic equipment.

Japan Keyence sensor control

LCD touch screen control

Cast aluminum integrated lifting platform

light tower and audible alarm

CE compliance.

2 year parts warranty

Technical Specifications:

Selectable pitch 10mm up to 40mm

Auto/Manual run modes

Diameter 3mm edge round belt

Component clearance: top 80mm bottom 20mm

Power: AC220V/110V, 50/60 HZ, 1 phase

Air Pressure: 5kgf/cm2

PCB Convey Direction: L-R ( Or R-L)

Front rail fixed ( or rear rail fixed)

Conveyor height:900+-20mm( standard height for SMT application)

For AI application, please specify the height requirements

Magazine max pcb width available at 250mm(S), 330mm(M), 390mm(L), 460mm(X)

| Model No | Description | Magazine Size | Max PCB Size |

| UL250 | 250mm Magazine Unloader | 355x320x563 mm | 350x250 mm |

| UL330 | 330mm Magazine Unloader | 460x400x563 mm | 460x330 mm |

| UL390 | 390mm Magazine Unloader | 535x460x570 mm | 535x390 mm |

| UL460 | 460mm Magazine Unoader | 535x530x570 mm | 535x460 mm |

| Model No | Machine Dimension(L×W×H) | Net Weight | Shipping Dimension(L×W×H) | Gross Weight |

| UL250 | 1680×765×1200mm | 210 kgs | 1830×930×1420mm | 290 kgs |

| UL330 | 1920×850×1200mm | 230 kgs | 2080×1010×1420mm | 320 kgs |

| UL390 | 2160×910×1200mm | 270 kgs | 2310×1060×1420mm | 360 kgs |

| UL460 | 2160×980×1200mm | 280 kgs | 2310×1130×1420mm | 370 kgs |

Contact Details

Whether you'd like to get more info on what,why and how we do what we do, need help with what you're creating,would line to partner up or just say hi!

—--- We'd love to hear from you.

Note : Your information detail will not be published. Required fields are marked*

ASCEN

ASCEN ASCEN

ASCEN ASCEN

ASCEN