ASCEN

Video Channel

Follow us on

ASCEN

Video Channel

Follow us on

Skype:supplier889 Email:info@ascen.ltd WhatsApp/Line/Phone:8613377777085

PRODUCTS

- PCB separator

- hektor separator/PCB hektor/off-out V-cut separator

- PCB Loaders

- PCB Unloaders

- PCB depaneling

- PCB Conveyors

- PCB Outfeed Conveyor|PCB belt conveyor

- Infeed Conveyor

- AGV car/Guided transfer robot/load efficient/magnetic navigat

- PCB magazine loader

- PCB Buffers

- Component insertion feeder

- Auto Screw Fastening Robot

- Traffic Control Conveyors

- PCB depaneling machine

- Wave Soldering

- Lead Free Reflow Oven

- PCB grooving machine

- solder dross separator

SOLUTIONS

CONTACT US

SOLUTIONS

Product Description

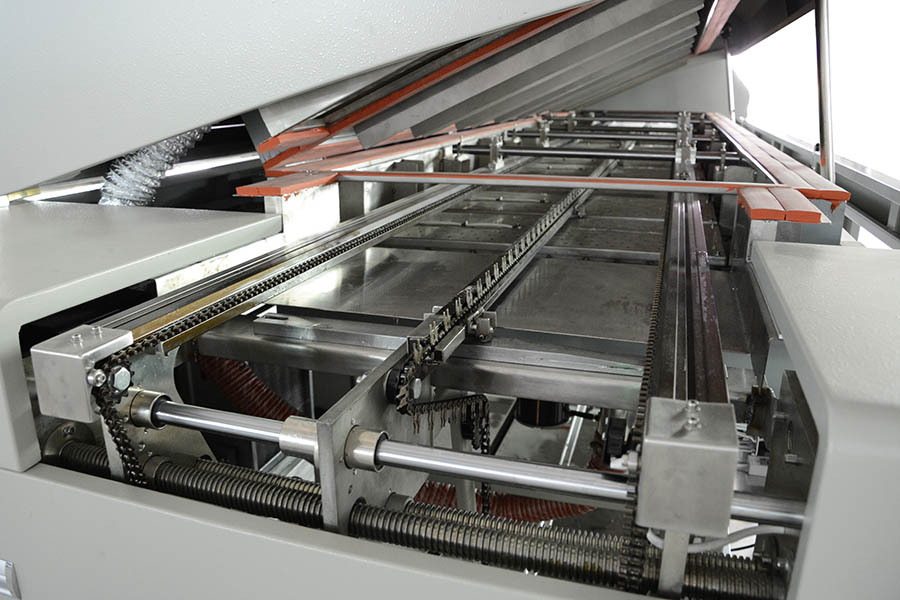

8 & 10 Zone Reflow Oven

Application:

Forced hot air reflow oven with eight ( or ten) top and eight ( or ten) bottom heating zones, CR8000(10000) is ideal solution for high volume production. With a maximum temperature of 350 degrees C, CR8000(10000) is compatible with most of lead and lead free solder paste profiles.

Technical Specifications:

Power 3 φ, 380 V, or 3 φ, 220 V, Pin Conveyor Width: Max 450mm

PCB Max Width on mesh : 550mm Height of Conveyor: 900mm+50/-20mm

Conveyor Speed: 0.4~1.8m/min Conveying Direction: L-R( or R-L)

Heating Tunnel Length 2700/3400mm Component Max Height: upper 30mm, lower 25mm

Ramp Up Time ≤25min Temp Range Ambient~350°C

Heating Mode: hot air forced convection Temp Control Mode PID+ SSR

Precision of Temp Control ±1°C Delta T ±2°C

Application:

Forced hot air reflow oven with eight ( or ten) top and eight ( or ten) bottom heating zones, CR8000(10000) is ideal solution for high volume production. With a maximum temperature of 350 degrees C, CR8000(10000) is compatible with most of lead and lead free solder paste profiles.

Technical Specifications:

Power 3 φ, 380 V, or 3 φ, 220 V, Pin Conveyor Width: Max 450mm

PCB Max Width on mesh : 550mm Height of Conveyor: 900mm+50/-20mm

Conveyor Speed: 0.4~1.8m/min Conveying Direction: L-R( or R-L)

Heating Tunnel Length 2700/3400mm Component Max Height: upper 30mm, lower 25mm

Ramp Up Time ≤25min Temp Range Ambient~350°C

Heating Mode: hot air forced convection Temp Control Mode PID+ SSR

Precision of Temp Control ±1°C Delta T ±2°C

| Model | CR8000 | CR10000 |

| Heating Zone Qty | 8 ( up and down ) | 10 ( up and down ) |

| Heating Tunnel Length | 2700mm | 3400mm |

| Cooling zone Qty | 2 | 2 |

| Power Consumption | 10~14kw | 11~16kw |

| Total Power | 60kw | 70kw |

| Exhaust Vents Qty | 3 | 3 |

| Exhaust Opening Size | 8"x3 | 8"x3 |

| Total Exhaust Venting | 390 CFM | 390 CFM |

| Net Weight | 2000 kgs | 2100 kgs |

| Gross Weight | 2330 kgs | 2430 kgs |

| Machine Dimension | 4800(L)×1510(W)×1550(H)mm | 5500(L)×1510(W)×1550(H)mm |

| Shipping Dimension | 5200(L)x1850(W)x1950(H)mm | 5900(L)x1850(W)x1950(H)mm |

| Power | 3 φ, 380 V,95A /3 φ, 220 V,160A | 3 φ, 380 V,110A /3 φ, 220 V,190A |

| Nitrogen Available | Yes | Yes |

| N2 Consumption | 20-35 m3/h | 36-42 m3/h |

| Oxygen Density | 500-1000 ppm (with N2 only) | 500-1000 ppm (with N2 only) |

Contact Details

Whether you'd like to get more info on what,why and how we do what we do, need help with what you're creating,would line to partner up or just say hi!

—--- We'd love to hear from you.

Note : Your information detail will not be published. Required fields are marked*

ASCEN

ASCEN ASCEN

ASCEN ASCEN

ASCEN